Empowering Women in Engineering

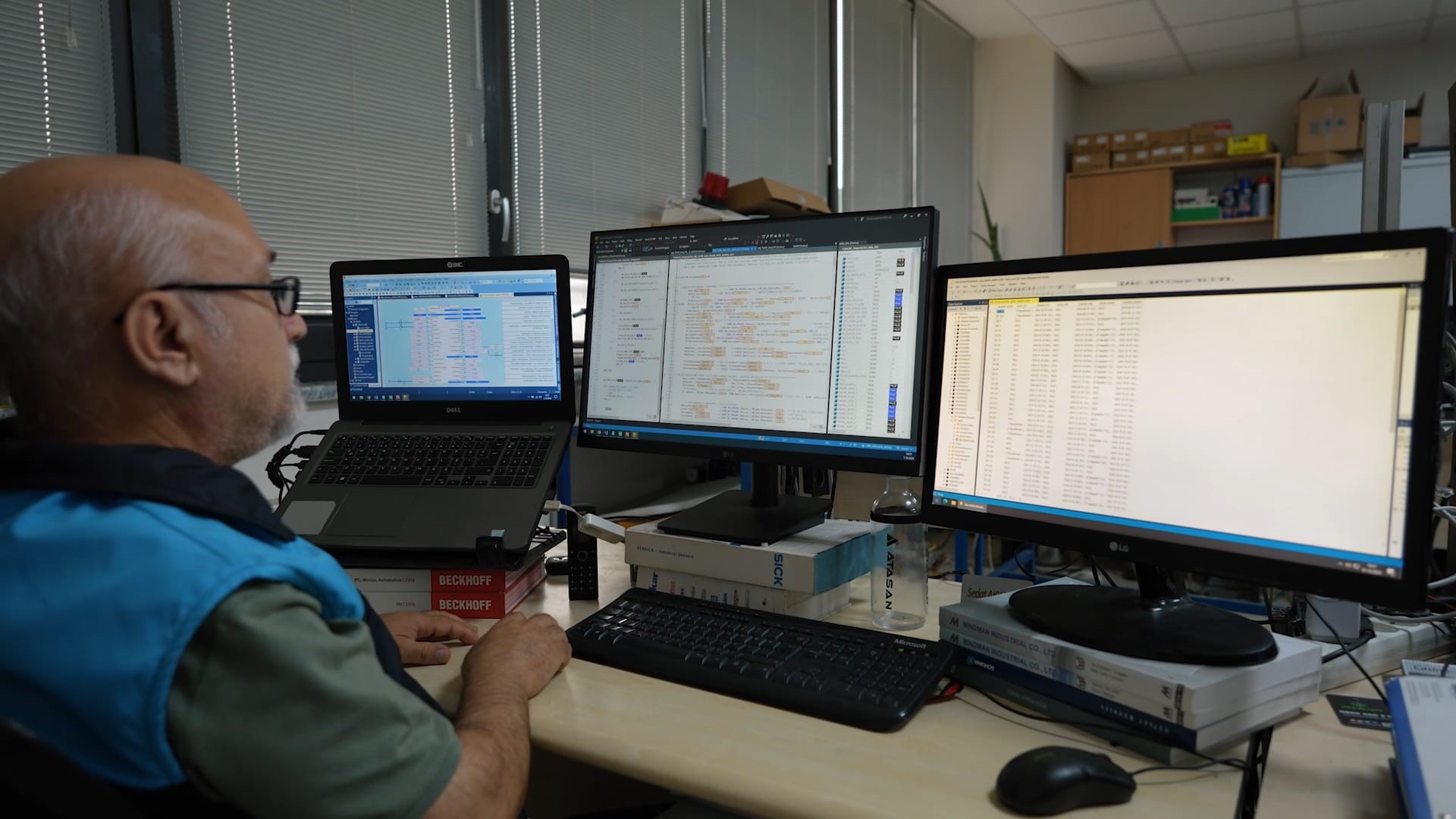

A high percentage of our white-collar professionals are women, leading innovation and shaping the future of precision manufacturing.

From our roots in Turkey to our new presence in the U.S., Atasan is now locally available and supported across North America.

With over 30 years of experience manufacturing precision metal components, Atasan Metal Sanayi ve Ticaret A.S. (Turkey) has become a trusted partner for OEMs worldwide. Atasan Inc. (USA) brings the same engineering excellence and reliability to the U.S. market — offering local sales, support, and services while importing products from our LEED-certified facilities in Turkey.

To better serve customers and strengthen our footprint in North America, Atasan Inc. (USA) was established in 2024 as a wholly owned U.S. subsidiary of Atasan Metal Sanayi ve Ticaret A.Ş. Beginning in late 2025, Atasan Inc. (USA) will manage sales, contracts, and customer support for all new U.S. customers, providing localized service and faster delivery.

Products will continue to be manufactured in Turkey and imported by Atasan Inc. (USA). As part of our long-term strategy, we are also exploring future local manufacturing opportunities in the U.S. to better support regional demand.

Existing U.S. customers of Atasan Metal Sanayi ve Ticaret A.S. (Turkey) will continue to be served directly from Turkey, while new U.S. customers benefit from Atasan Inc. (USA)’s local presence and support.

Atasan Inc. – Based in Boston, Serving the U.S

Serving the U.S. with sales, warehousing, customer support, and local deliveries.

Products are manufactured in our LEED-certified facilities in Turkey and imported for U.S. customers.

All new U.S. clients are supported locally with faster service and reliable supply.

World-Class Manufacturing in Turkey, LEED-Certified

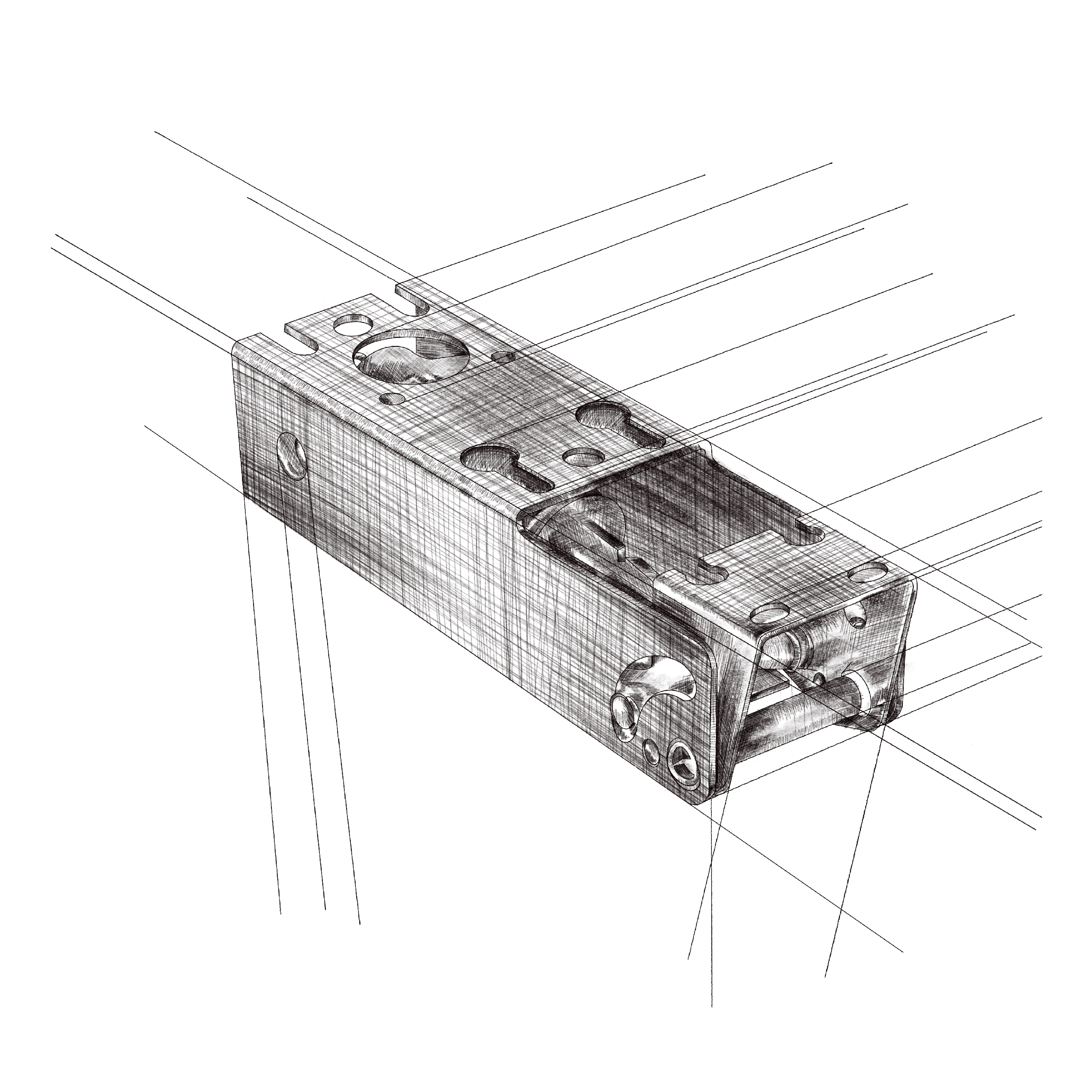

Our Turkish facilities combine advanced technology and skilled craftsmanship to produce high-quality metal components and motion systems for demanding global industries.

In 2024, we took the next step in our journey by establishing Atasan Inc. in Boston, Massachusetts — marking a new chapter in our expansion into North America.

This strategic move allows us to offer faster delivery, localized support, and tailored solutions for U.S.-based customers. Today, Atasan Inc. (USA) manages sales, customer support, and distribution for new clients while continuing to rely on our state-of-the-art, LEED-certified manufacturing facilities in Turkey.

Our mission is simple: to deliver the same exceptional quality and reliable service our partners have trusted for over 30 years — now with the added benefit of a local presence and faster delivery in the U.S.

Looking ahead, we remain committed to innovation, sustainability, and the growth of our operations in both Turkey and North America. Atasan is not just a manufacturer — we are a long-term partner in our customers’ success, continually evolving to meet the needs of an ever-changing world.

A high percentage of our white-collar professionals are women, leading innovation and shaping the future of precision manufacturing.

70% of our professionals have been with Atasan for over 10 years

We design and build many of the specialized machines used in our own production, ensuring full control over quality and innovation.